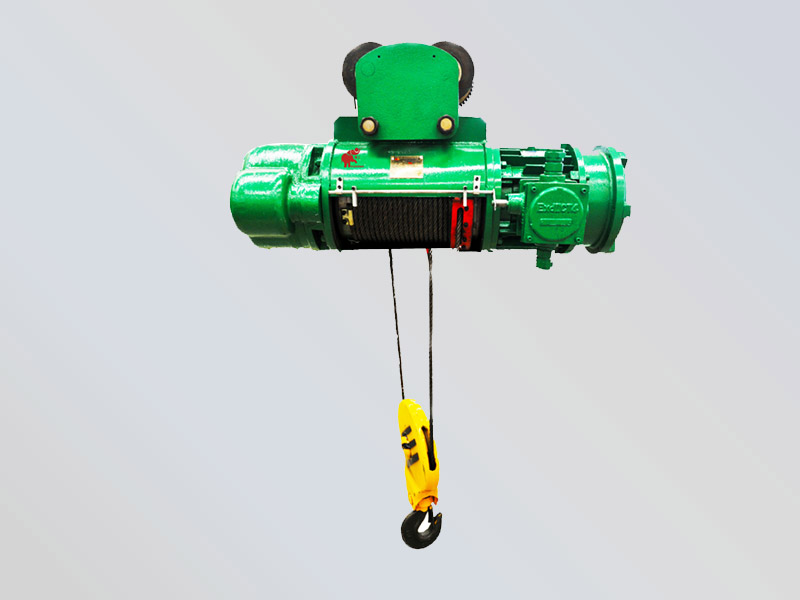

Product Description

Our Explosion-Proof Electric Hoist is engineered for safe operation in flammable, explosive, or volatile atmospheres, such as oil refineries, chemical plants, gas stations, grain silos, and mining facilities. Certified for Zone 1/21 and Zone 2/22 hazardous areas, this hoist integrates explosion-proof technology with robust construction to prevent ignition risks while handling loads up to **[X tons]**. Ideal for industries requiring ATEX, IECEx, or NEC compliance, it ensures maximum safety and performance in high-risk environments.

Key Features:

1. Explosion-Proof Design

- Ex d (Flameproof) Motor and Electrical Components: Prevents internal sparks from igniting external gases.

- Anti-Static Materials: Non-sparking alloy hooks and galvanized chains/wire ropes.

- Sealed Enclosures (IP66): Protects against dust, moisture, and corrosive substances.

2. Advanced Safety Systems

- Intrinsically Safe Control Circuitry (IS Certification)

- Thermal Overload Protection with Automatic Cutoff

- Emergency Stop Button with Lockout Mechanism

3. Durable & Corrosion-Resistant

- Stainless Steel or Copper-Free Aluminum Components

- Epoxy-Coated Surfaces for Chemical Resistance

- Reinforced Braking System for Sudden Load Shocks

4. Precision & Flexibility

- Variable Speed Control (0.5–10 m/min)

- Low-Voltage Pendant or Wireless Remote Control (Explosion-Proof Certified)

- ±3mm Positioning Accuracy

5. Smart Monitoring

- Real-Time Load and Temperature Sensors

- Fault Diagnostics via LED Display

- Optional IoT Integration for Remote Supervision

Competitive Advantages:

Certified Safety

Complies with ATEX 2014/34/EU, IECEx, NEC 505/506, and ISO 80079 standards for global hazardous-area compliance.

Zero Ignition Risk

Rigorous testing ensures no sparks, arcs, or hot surfaces exceed the auto-ignition temperature of specified gases/dusts.

Extended Service Life

Corrosion-resistant materials and sealed bearings reduce wear in harsh environments, offering 20% longer lifespan than standard hoists.

Energy Efficient

IE3 Premium Efficiency Motor reduces power consumption by 15–20%.

Easy Maintenance

Modular design with quick-access panels minimizes downtime during inspections.

Typical Applications:

- Petrochemical plant material handling

- Grain elevator lifting operations

- Paint spray booth logistics

- Offshore platform equipment maintenance

- Pharmaceutical powder processing

Customization Options:

- Explosion-Proof Class: Ex d IIC T4/T5/T6, Ex tb IIIC T85°C

- Voltage: 220V–660V, 50/60Hz

- Control Systems: Fiber-optic remote, pneumatic controls

- Special Coatings: Acid-resistant, anti-abrasion